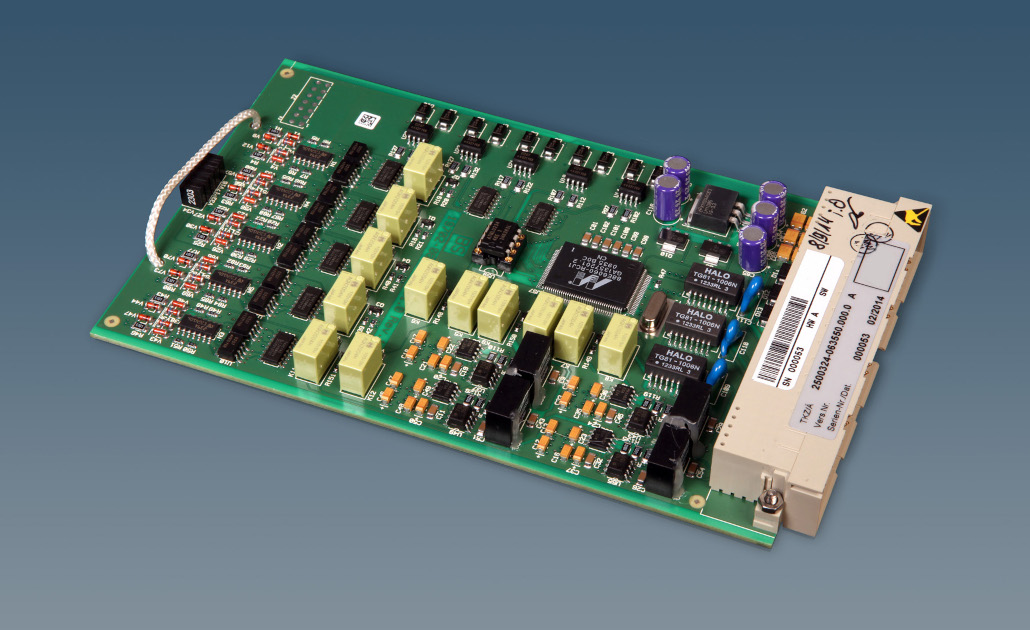

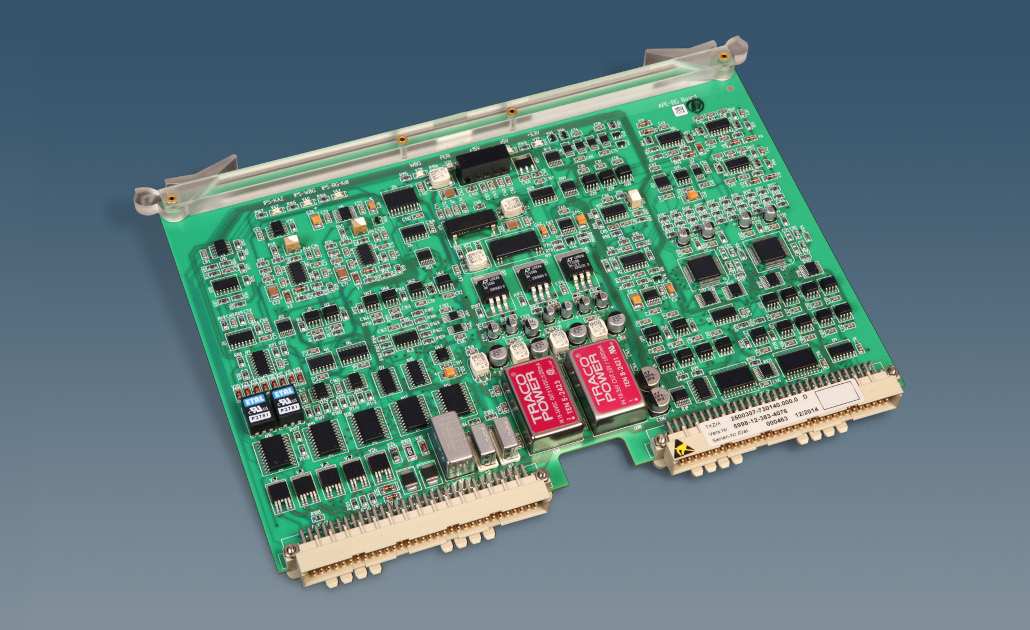

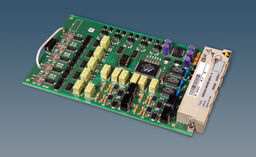

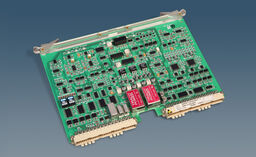

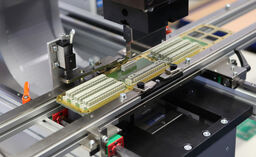

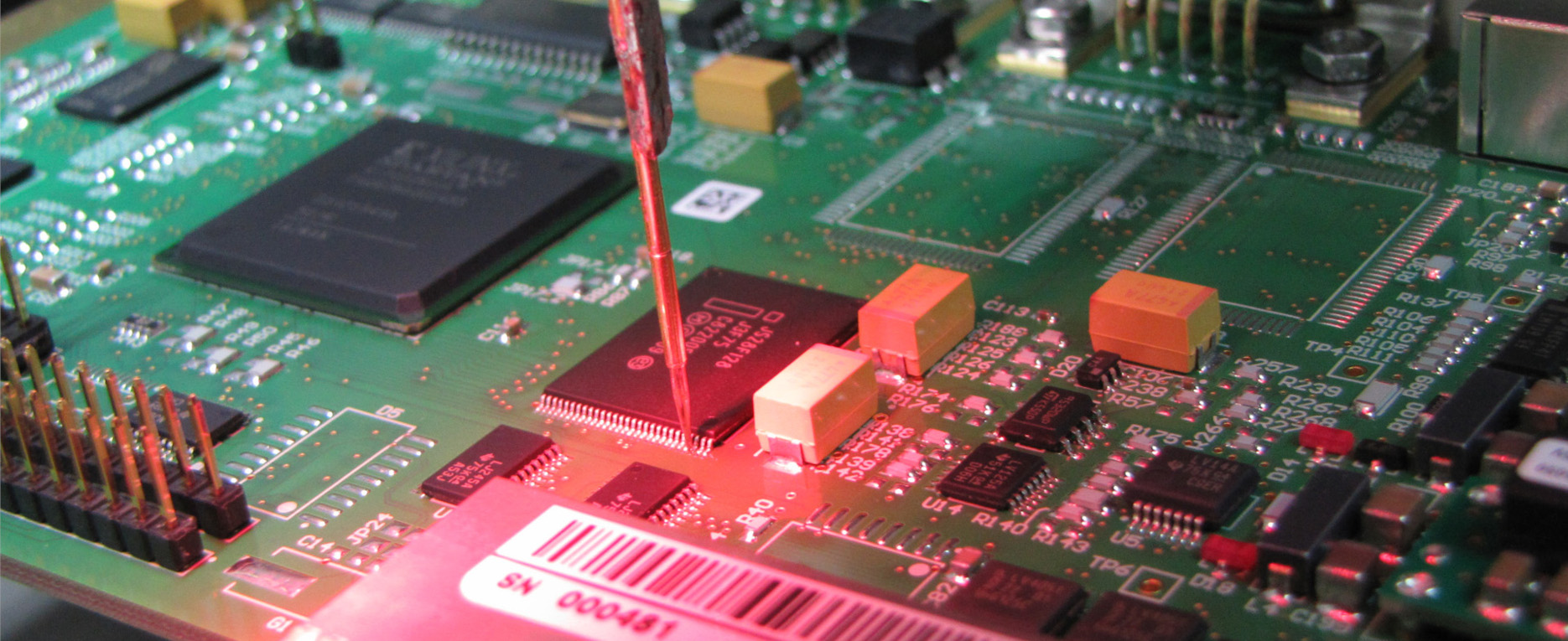

Automated production of electronic circuit boards in SMT and THT technology with a component spectrum ranging from 0201 to high-pin BGA components for motherboards, components for video and image processing and communication technology as well as signal, control and power electronics

Performance characteristics for the printed circuit board manufacturing process

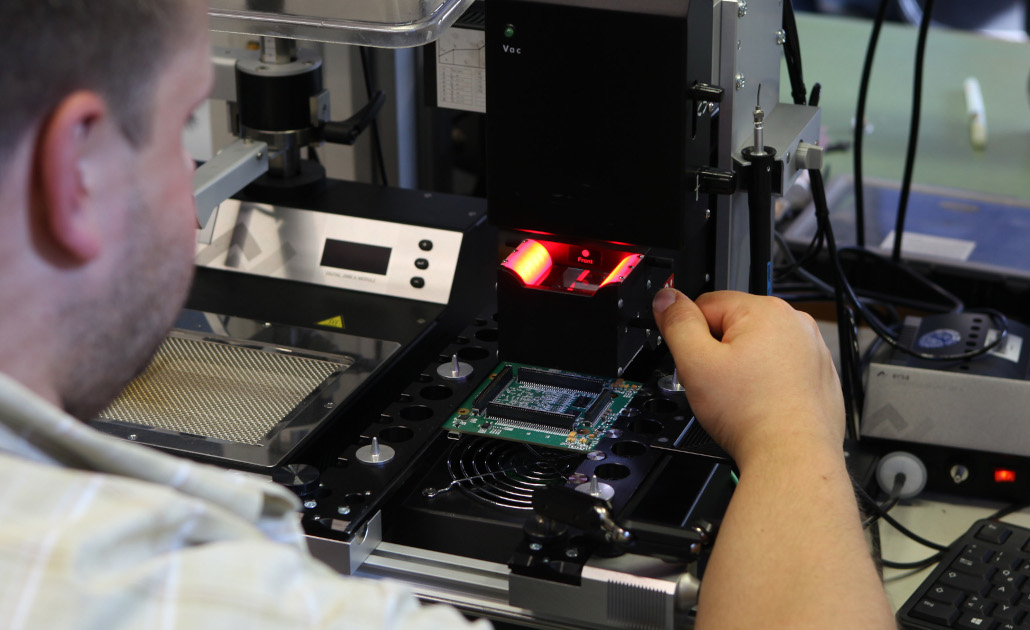

To meet our high quality standards, the functioning of every manufactured product is 100% tested before delivery.

The safe use of lead-free or lead-based connection technology throughout the entire process chain is ensured by using state-of-the-art equipment and process controls. Our employees in production are trained and certified according to IPC.

All steps are consistently traceable across the value stream down to the component level.

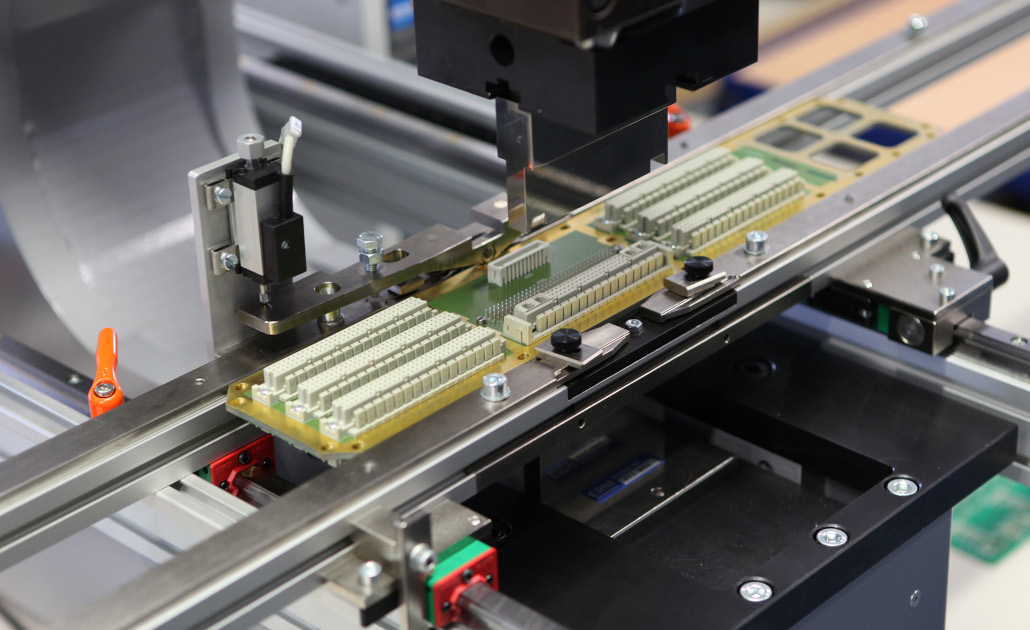

A gas-tight and solder-free assembly of connectors for PCBs and motherboards is possible.

Facts about PCB production

More than 40 years of know-how in electronics production is the basis for a successful partnership with our customers. We develop and manufacture prototypes, pilot series, batch sizes of 1 and small series; we furthermore carry out modifications and repairs. Our central component warehouse enables us to react very flexibly and at short notice to customer requirements.

Our goal is to plan and implement customer-specific solutions for the most efficient manufacturing of cables and cable harnesses, EMC-protected cable harnesses, electrical devices and printed circuit boards. We can process encrypted electronic product and design data. Our highly qualified personnel and modern machinery are deployed for this purpose. The experience and professionalism of our employees ensure the quality and reliability of our products.

Printed circuit boards for use in high-tech and complex assemblies

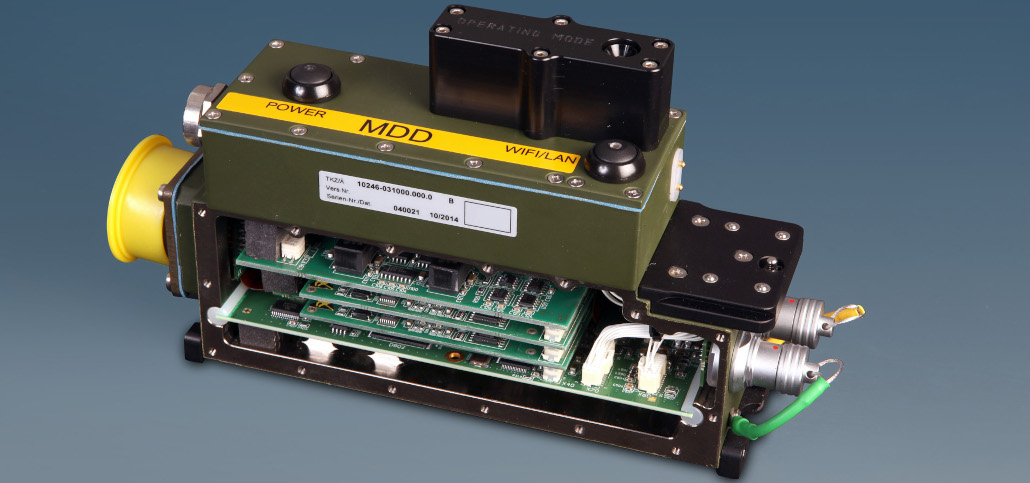

Our finished units are used in all land systems from KNDS Deutschland as well as in many systems from external customers.

Performance characteristics of printed circuit board manufacturing

- New production, modification and repair of printed circuit boards

- Prototypes, pilot series, batch sizes of 1 and small series

- Highest flexibility and shortest response times

- Leaded or lead-free connection technology throughout the entire production process

- Range of components from 0201 to BGA and odd-shape

- Gastight and solderless connector press-fit technology

- Traceability over the entire production process

- Highest reliability through 100 % functional testing of all manufactured assemblies according to customer specifications

- Design, manufacturing and programming of all necessary test equipment in the factory

- Certification according to current:

- DIN EN ISO 9001

- AQAP2220/2210

- VDE-monitored production facility

- WTG81 EMC certification

- ISO 14001

- ISO 5001

PCB production in pictures

Images of manufactured printed circuit boards from various application areas